DMS On-line Monitoring System

for Life of Machining Tool

Independently developed by Taiwan & Patented

Principle

The state of cutting tool is monitored instantly by means of vibrating signals produced by the main shaft of the machine or the working environment during cutting operation and single difference factor is derived with the patented 1 technology. The difference factor can be used to judge life and abnormal damage of the cutting tool instantly and easily.

Description

- The feature comparison model is established quickly and easily by using the vibration acceleration data of a complete processing process.

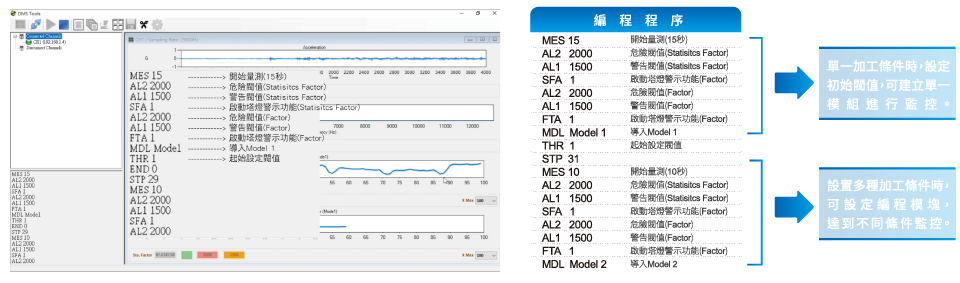

- Monitoring conditions can be switched in real time according to different machining parameters or cutting tools.

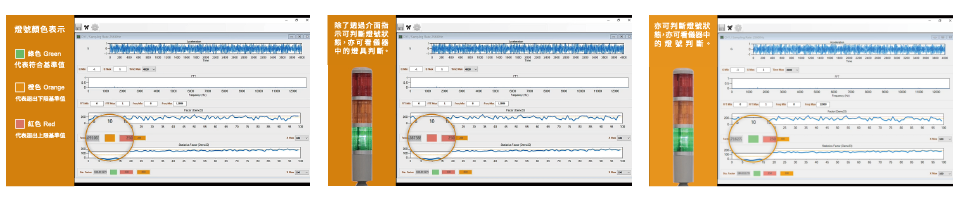

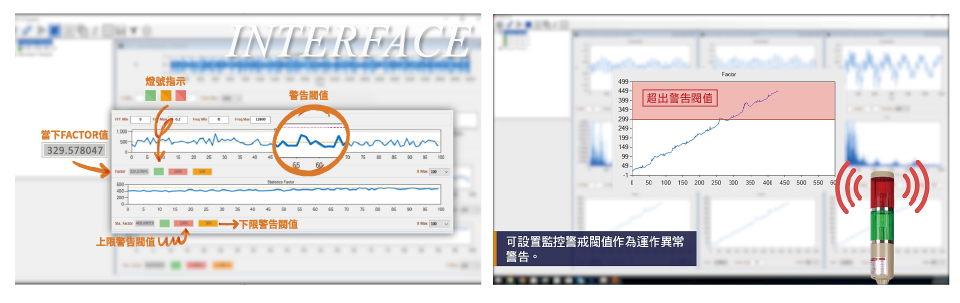

- A monitoring threshold value can be set for the output difference factor can be set for real-time alarm.

- Light signals are used to remind the staff on the spot to take effective troubleshooting measures for abnormal processing conditions.

- The collection of pointer data of single difference factor can be applied to big data analysis and the practice of artificial intelligence.

- Collection and storage of comparison pointer data for the establishment of automatic detection mechanism for abnormal conditions can achieve intelligent learning of machine

Features

- Instant detection during processing is helpful for enhancing machine utilization.

- Intelligent establishment of difference comparison model for easy operation.

- Differentiation diagram can present the abnormal conditions during processing specifically and are helpful in objective judgment.

- Intelligent learning abnormal states including life or breaking of cutting tool is different from the traditional judgment method and can reduce the possibillity of subjective misjudgment.

- The life of cutting tool can be estimated effectively according to the data regarding long-time cutting trend collected and deduced.

- Multiple signal interfaces are available to work with different kinds of CNC machines.

- The yield of finished products can be improved and the rejection rate can be reduced.

- The labor cost can be reduced greatly to achieve the target of Automated Industry 4.0.

Application Field

- Utilization of the machine and the efficiency of batch production can be improved.

- Abnormal processing that may cause poor quality or machine damage.

- The cutting tool cost too high or the breaking or damage of cutting tool happens frequently.

- It is impossible to judge the time of changing the cutting tool instantly to produce the rejection rate high.

- The target is Industry 4.0 to achieve automated and intelligent monitoring and manufacturing.

software - So Friendly

The DMS(Dynamic Mechanical System) judge the life time of knife by factor and establish the management system.

Pass/fail - So Easy

After set threshold, operator can get alarm from software and lamp.